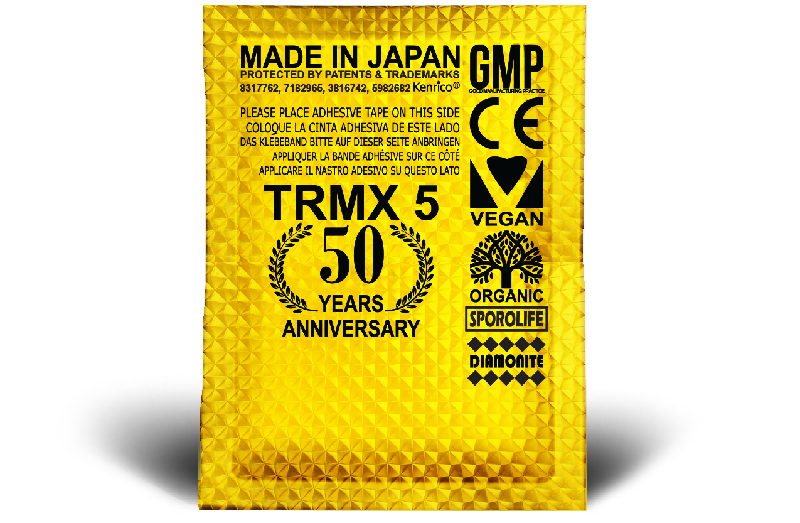

Kenrico's

State-Of-The-Art

Certified Factory In Japan

The making of Kenrico SAP sheet

I. FORMULA PREPARATION

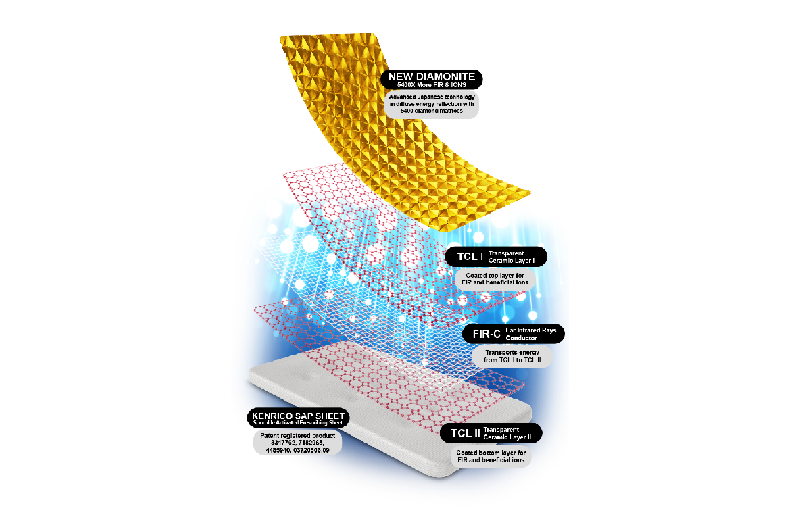

Kenrico's patented formulation and materials such as Sporolife®, ZeoCell®, and Diamonite® are manufactured and stored at Kenrico state-of-the-art facilities.

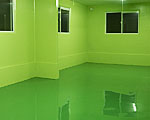

Kenrico's certified facilities are equipped with HVAC system to ensure that the air quality and temperature are controlled. Since 2020, Kenrico's facilities are germ-free in accordance to Reaching Zero standard.

II. PRECISION SCALING - PRE PRODUCTION

Each composition and material are measured with 4 digits precision scaler to ensure extreme precision.

4 digit precision scaler.

III. FORMULA DEVELOPMENT

Composition containing Sporolife® and ZeoCell® are carefully prepared according to their patented formulas.

High capacity drum mixer.

IV. PRECISION SCALING - POST PRODUCTION

Finished formula is weighted for the second time for Quality Assurance.

4 digit precision scaler.

V. SINGLE PROCESSING BATCH

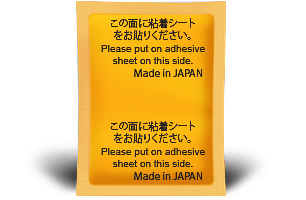

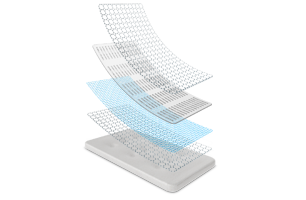

SAP Sheets are processed into a patch according to their manufacturing patents.

Printing machine model: CP-4FP.

Seal roller: 20 RPM.

Temperature of sealing (length): 115 +- 5 C.

Temperature of sealing (width): 105 +- 5 C.

Cutter: 1 block.

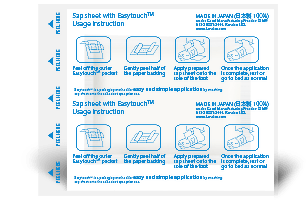

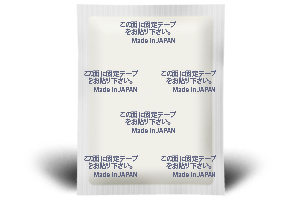

Easytouch machine model: JPROBO-10.

Seal roller: 10 RPM.

Eye sensor: 2.

Temperature of sealing (length): 90 +- 5 C.

Temperature of sealing (width): 80 +- 5 C.

Cutter: 4 blocks (Sap sheets, Adhesive tapes,

Paper backing, PE plastic).

High quality printing, roller, and cutter machines.

Easytouch machine combines adhesive sheet and SAP Sheet pad together into one single device. The Diamond Hybrid Edition DHE 30th Anniversary and the Quick edition QU-1 are manufactured with Easytouch machine.

Kenrico SAP Sheet can be individually labeled with sequential numbers to ensure quality control.

VI. POST PROCESSING

Kenrico SAP Sheets are individually sealed inside a patented airtight plastic sleeve (KENRICO SHIELD) to protect the devices against germs.

-

Kenrico Quality Assurance team operates under CE medical standard to ensure that:

- SAP Sheet is properly sealed inside an airtight plastic sleeve.

- SAP Sheet is free of contaminants and germs.

- SAP Sheet is produced according to its formula.

Our fast and reliable Q/A team.

VII. RESEARCH AND DEVELOPMENT

Ongoing research is vital for creating innovative products that ensure continuous cures for human health. Kenrico R&D consists of medical doctors that continue to research and to develop new life-changing products and formulations.

Kenrico tenacious R & D team.

Germ-free facility at Kenrico with HVAC system and protected by HEPA and ULPA filters.